Digital Fabrication, Makerspaces, and Studio Leadership

I am an experienced teacher and practitioner of CAD, CAM, and digital fabrication with extensive background overseeing academic makerspaces and fabrication labs in liberal arts settings. My work spans hands-on instruction, student project advising, faculty consultation, equipment operation and maintenance, and program leadership.

I specialize in building accessible, well-run shops that students and faculty actively want to use—spaces grounded in safety, precision, mentorship, and sustained engagement with materials and ideas.

Curricular Support & Teaching

A core part of my work has been direct instruction and supervision of students completing fabrication-based coursework across STEM, design, and the arts.

I regularly taught and supported:

CAD and drafting workflows

material selection and prototyping strategies

safe operation of fabrication equipment

iterative design and model-making

Instruction took place through:

scheduled class visits

group training sessions

extensive one-on-one mentoring

Many students arrived with strong ideas but uncertainty about how to execute them. Helping students identify appropriate tools, software, and materials—and then guiding them through production—was the everyday reality of my work in university labs.

Tools & processes taught

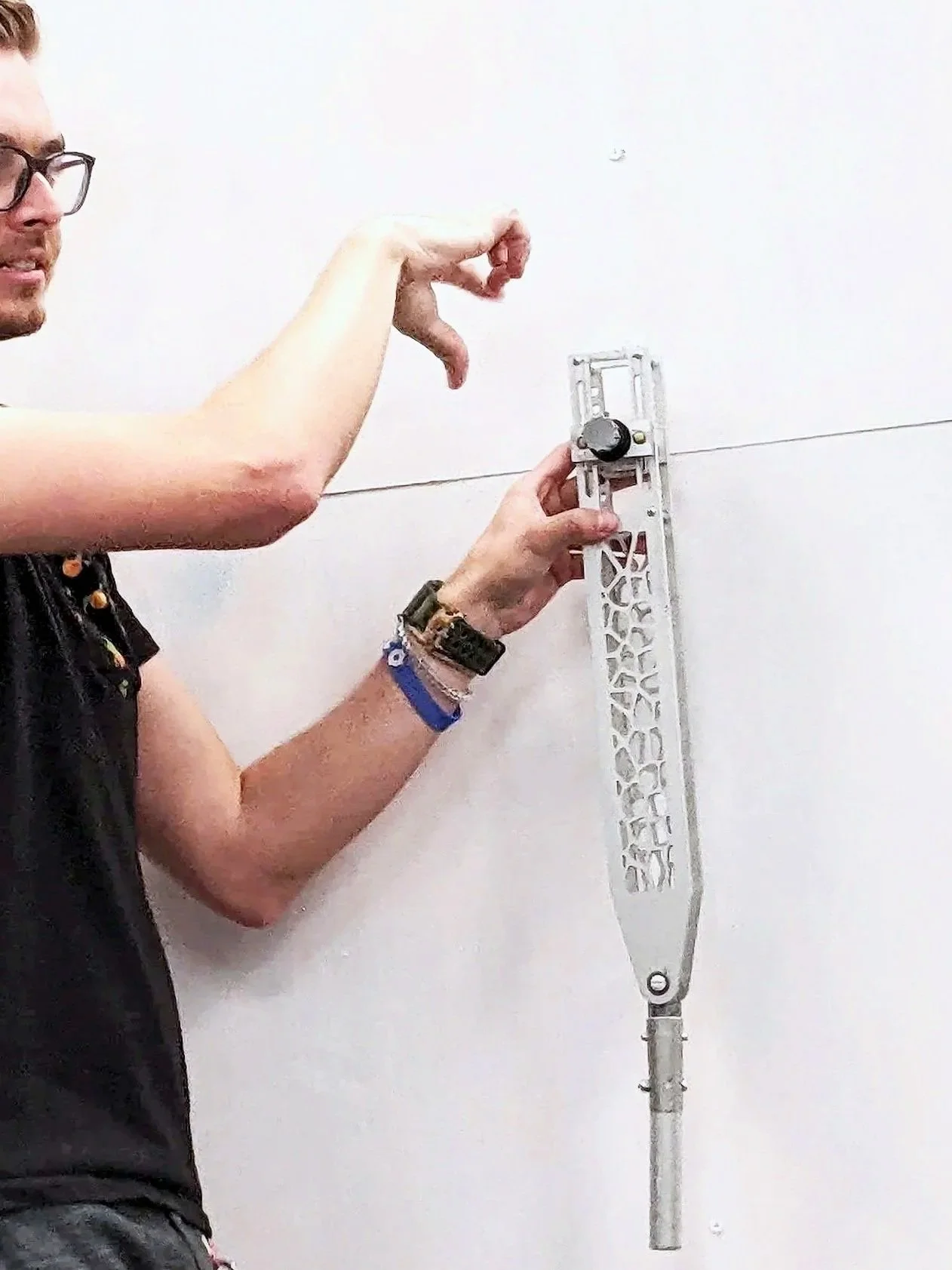

CNC milling (toolpathing, fixturing, workflow planning)

laser cutting and engraving

3D printing (multiple platforms, slicing, troubleshooting)

3D scanning and digital capture

digital illustration and vector workflows

large-format printing and scanning

Project Advising & Consulting

I have extensive experience serving as a campus-wide fabrication consultant for:

honors theses

independent studies

research projects

faculty-led experimentation

At Wesleyan University, I worked closely with students, staff, and faculty to:

develop experimental designs

select materials and fabrication methods

prototype and refine designs

fabricate tools, components, and research artifacts

provide hands-on training in equipment and safety

This work often involved close collaboration over long timelines, helping projects evolve from early concepts into functional, well-executed outcomes.

I also supported grant development by advising on technical feasibility, equipment needs, and fabrication workflows.

Makerspace Operations & Program Leadership

I have overseen daily operations and long-term planning for academic fabrication facilities, including budgeting, staffing, scheduling, and reporting.

At Wesleyan, I directed and expanded the Digital Design Studio (DDS) through competitive funding from the Mellon Foundation and the Sherman Fairchild Foundation, supporting:

infrastructure expansion

staffing and training models

equipment acquisition and lifecycle planning

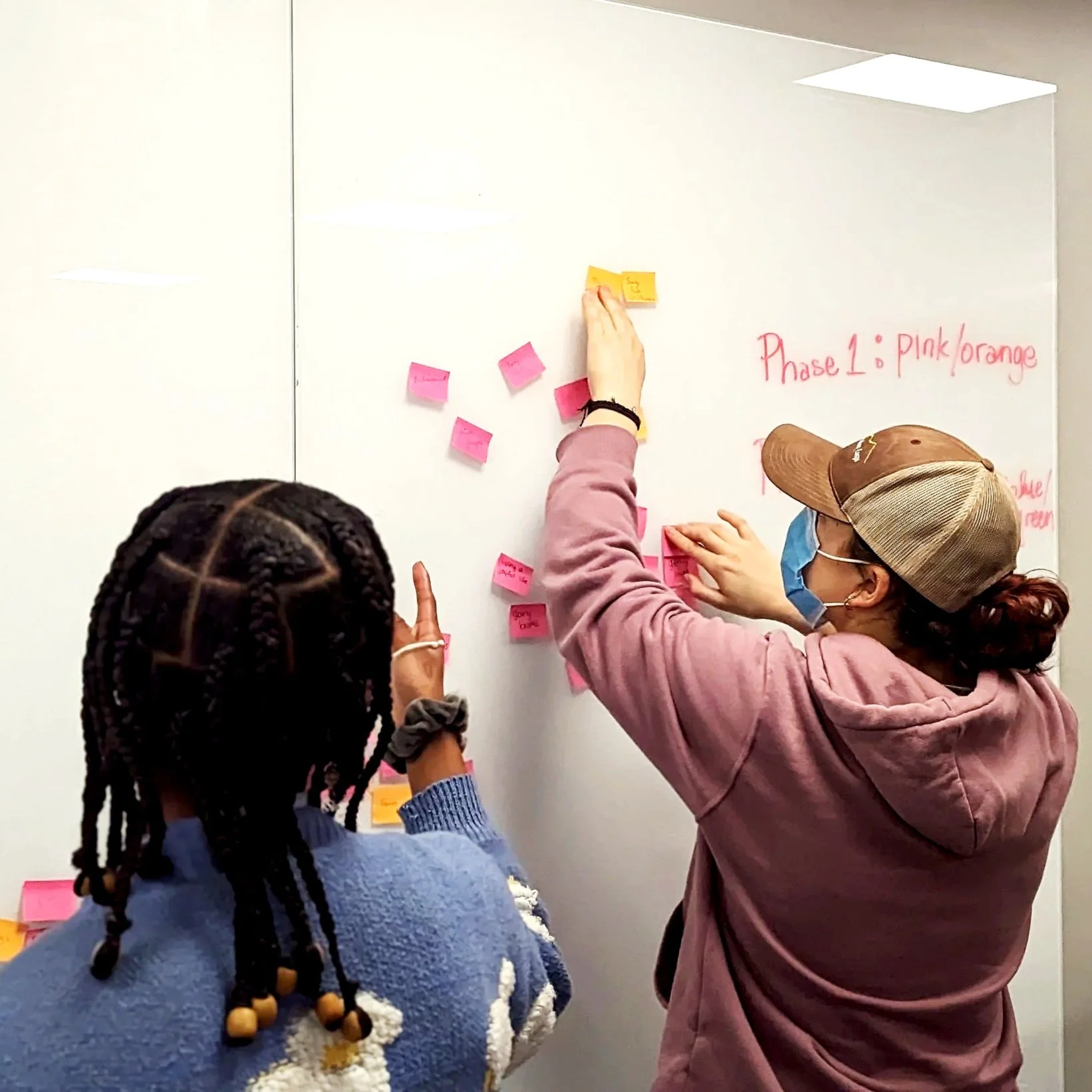

Our team developed a peer support model, hiring, training, and managing 7–10 student staff per semester. This model emphasized:

safety

peer mentorship

technical competency

leadership, accountability, and stewardship

inclusive hiring and professional development

creative problem solving, collaboration, and empathy

Over seven years, the DDS served 300+ users each semester with a zero-accident safety record.

Technology Support & Capital Management

I have hands-on experience operating, maintaining, and troubleshooting a wide range of fabrication equipment and associated software.

My work has included:

routine calibration and maintenance

machine setup and cleaning

software configuration and updates

workflow scheduling around courses and research

documentation and safety enforcement

My technical background spans:

CNC machining (conventional and CNC)

3D printing (multiple platforms)

laser cutting

woodworking and fabrication

digital scanning and capture

electronics and basic physical computing systems

I emphasize preventive maintenance, careful documentation, and shared responsibility to keep facilities reliable and safe.